Walvoil, solutions to optimise energy consumption

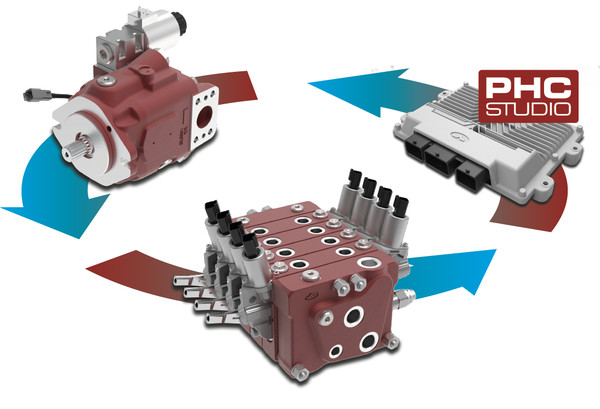

There is a growing demand in the self-propelled machinery market for vehicles designed to raise the performance bar while reducing both operating costs and emissions. In this respect - explains Walvoil, a historic group engaged in the production of components and systems for the agricultural machinery sector as well - several studies have shown that up to 40% of the energy supplied to the hydraulic system of the operating machine is dissipated by the limited efficiency of the components and by the pressure losses generated for the adjustment and control of movements. The problem - adds the manufacturer - is also evident on electrified applications, where energy efficiency is synonymous with autonomy and reduced battery capacity. For this reason, the Emilian-headed manufacturer has developed technological solutions that allow consumption to be cut by up to 25%. The first is the ALS system which, through the joint control of the hydraulic distributor and the pump, makes it possible to reduce pressure losses due to the pressure margins of the adjustment system. The ALS can be either used as an integral part of the hydraulic distributor or fitted on the variable displacement pump. The ALS system is available in three versions: among these, the LS Electronic Control is designed to perform pressure control functions in combination with Flow Sharing distributors of the DPX and EPX series. The system manages and conditions the Load Sensing signal of the circuit to reduce consumption and optimise control. Thanks to the possibility of integrating the ALS system directly inside the valve, it can also be used with fixed displacement pumps. The ALS - Flow Control configuration, on the other hand, combines a normal open-centre, electro-proportional control valve with the electronically controlled variable displacement pump with ALS logic. The variable pump provides the flow rate according to the settings defined by the operator through dedicated software. With this configuration, the Flow Control type technology guarantees better load adjustment and greater vehicle stability, as well as a significant reduction in consumption. Management of the electronic part is entrusted to the control unit with dedicated PHC STUDIO software. Another innovation offered by Walvoil at EIMA 2022 is the EPX technology - meter out compensation, awarded with an EIMA 2022 Mention. The EPX Series directional valves are a new range of electro-proportional control valves made to allow the management and recovery of hydraulic energy in self-propelled machines. Recovery can take place in an active manner during simultaneous drives of multiple machine functions, or in a passive manner by re-using the inertial energy that is usually lost as a result of fluid lamination towards the outlet. The energy thus 'gained' - continues Walvoil - can be stored in hydraulic accumulators, but it can also be used to charge a set of batteries through a hydraulic motor connected to an alternator and an inverter, or, depending on the options chosen by the manufacturer, to power the hydraulic system that manages the main functions of the machine.