Walvoil, command and control systems for every operational need

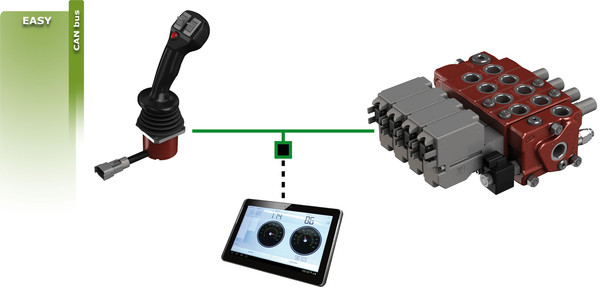

At the SIMA in Paris, Walvoil, now part of the Interpump Group, presents the evolution of its command and control systems dedicated to harvesting machines, tractors and attachments, forestry machines, lifting and transport in agriculture. It starts with the BASE system, designed for markets with developing mechanization, which comprises manually or hydraulically operated oleodynamic valves. It is currently the most popular system in agricultural machinery, and extends toward the load sensing systems. The control interface with the operator is directed or modulated, to ensure an active "feeling" with the machine functions. Walvoil has included the following components on the Base system: SDE030-SDE060, solenoid direct activation distributor and CED160 electronic controller. Meanwhile, the EASY system fulfils the need for integration and arises from the fundamental role that electronics have had in recent years in the dialogue between machines and components on shared platforms, with the internationally recognized protocols ISOBUS and CAN bus, which enable the integration with machine systems. On this front, the Emilian company offers the Easy CAN bus for Telescopic loaders. There are two components that interact with each other on the CAN bus: the DPX100/HF distributor compensated by Flow-Sharing technology, proportional drives, high flow HiFlow sections, EME mechatronic controls, and the CJW proportional joystick. Finally, for the higher performance models, in which the hydraulic and electronic functions must be integrated with the machine system in a complete way, Walvoil offers the ADVANCED systems with oleodynamic valves that integrate the various hydraulic circuits, and ISOBUS network control of the CJW Joystick. Equipped with the SDM127/DLM127 proportional distributor – available in both open centre and closed centre or Load-Sensing – of the CJW proportional joystick (certified ISOBUS) and a CED252 electronic control unit, the Advanced ISOBUS system allows to combine high levels of operational safety (the control unit performs control functions that are typical of the application, controls the distributor, and monitors it) combined with excellent performance.