AW 1070, the first Comer-Weyhausen compaction roller

The AW 1070 is a new compacting roller from Atlas Weyhausen with the collaboration of Comer Industries. The AW 1070 is powered by a 62 kW engine for use in the construction industry for stabilizing soil for the construction of roads, runways and railway track beds

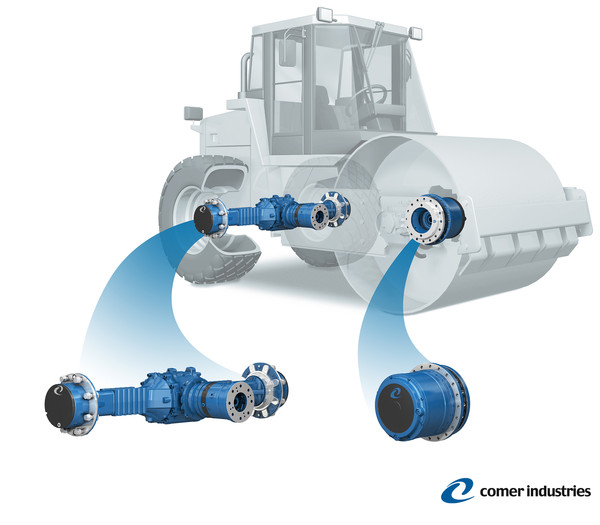

A partnership signed in June 2015 by Atlas Weyhausen GmbH, a German manufacturer of wheel loaders and compaction rollers for the construction industry, and Comer Industries in Italy has led to the development of the AW 1070 compaction roller model. The medium category roller designed for stabilizing soil for the construction of roads, tracks and railway track beds, has an operating weight of 7.1 tons and is powered by a 62 kW (84 HP) Tier2-Tier 3-Tier-4 engine. For the new machine, the German company aimed for new very strong and versatile drivetrain allowing a high torque as well as compact dimensions. The solution selected by Comer Industries was to work with two main components, a planetary drum drive to rotate the drum in the front and a bridge with a planetary gear for the rear part of the transmission. Up front, for the 1700 mm wide drum, with a diameter of 1250 mm, the decision was to use a two-stage PGRF-802 planetary drum drive, ideal for the requirements of AW 1070 compaction because high torque of up to a maximum of 7,967 Nm can be combined with compact design and low weight. Moreover, the planetary drum drive is built for mounting hydrostatic drive. For the rear part of the transmission, a combination of two Comer Industries’ advanced products work together. The total ratio of the planetary gear at axle input, axle differential and planetary gear at the hubs, is available from 47.6 up to 90.3. Comer Industries used a combination of the planetary gear PG-161 fitted to a F-128 axle. A technical communique issued by the Reggio Emilia manufacturer reported that the axle is an option fitted with a preloaded limited slip differential or No-Spin differential to guarantee efficient traction on different grounds. Moreover, mounting the planetary gearbox as well as the hydraulic motor at the level of the differential required less space compared to the standard drop box solution. Each single component of the drivetrain, the communique said, is geared perfectly to each other. The F-128 is designed to tolerate a maximum dynamic load of 6.6 tons with maximum torque at 24,000 Nm. Davide Gasparini, Area Manager Central Europe, commented, “Comer Industries’ complete driveline solution for soil compactors enables an improved fit between the hydrostatic and the mechanical parts of the transmission, minimizing the total cost and featuring compact design and highest ratio available.”