The new Capello corn headers offer top performance

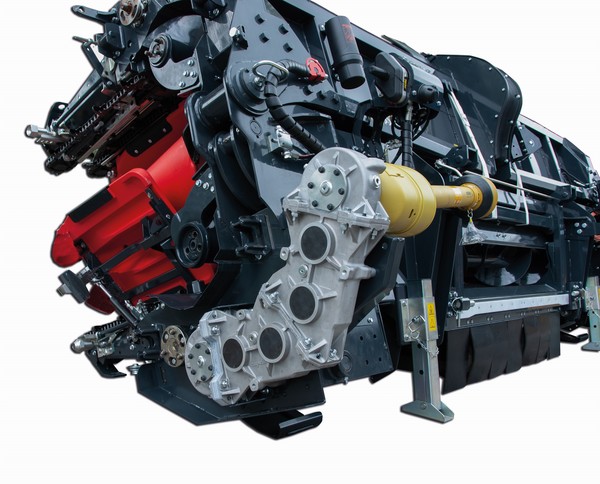

Capello has redesigned its Diamant folding corn headers. The folding 16-row version is debuting with an innovative lever-operated folding technology that closes the header in a compact position. Inspired by the handling systems used in shipbuilding for large weights, the new solution developed by the Cuneo-based manufacturer includes a lever mechanism whereby the hydraulic cylinders are no longer placed vertically, but horizontally above the frame. The repositioning of the cylinders reduces the hydraulic pressure required by the harvester during the opening and closing phases of the header and at the same time lightens the frame. The fulcrum points allow the cylinders and levers to work with less effort, while the levers, which are not welded but made of a single piece and joined with screwed bushings, improve the solidity of the entire system. The various components of the new leverage mechanism are also lighter and sized in such a way as to reduce as much as possible the weights in play, important for equipment that works “overhanging” on a combine harvester or a self-propelled forage harvester. Also on the 16-row Diamant machines, Capello has added a hydraulic system for moving the deck plates with a double cylinder, to grant the ability for the plates to move simultaneously and synchronously during the harvesting phase. It is the operator in the driving cabin who determines when to open the deck plates depending on the product being harvested. This synchronized movement allows the corn stalk to be centered with respect to the milk line of the plant: this makes the harvest clean, both for the greenest and the most extremely dry product, without loss of grain and without the entry of plant residues. Yet these are not the only new features in the Diamant range. Beginning in 2025, the Cuneo-based manufacturer will also change the main transmission box on all models with more than 10 rows. This innovative solution is designed to satisfy the combinations of motion required by each brand and model of combine harvester, and has a modular structure. The modules that compose it are made of aged aluminum alloy – a single cast with all gears having straight teeth and roller bearings – sized for high power demands. According to Capello toothed gearboxes offer better performance than bevel gearboxes due to lower energy dispersion.

On the straw cereal harvesting front, the Grain System Evo folding platform presents a significant innovation to the reel structure. The reel frame is hung and no longer suspended: a system that frees up space for the cut product inside the grain pan. The bottom of the frame is now entirely made of stainless steel (interchangeable inserts for wear) and is equipped with a stone guard to prevent stones or undesirable objects from getting in and damaging the internal moving parts. A new coupling with shock absorber joints has also been placed into the main transmission to transfer all the needed power without the risk of breakages and misalignments during the delicate phases of continuous levelling.