rante è un tutt’uno con l’albero di entrata del riduttore. Que-

st’ultimo ha alberi temprati, cementati e rettificati, che lavora-

no in bagno d’olio. Il tamburo è supportato da cuscinetti a te-

nuta ermetica esenti da lubrificazione e usura, a tutto vantag-

gio della riduzione degli attriti.

Terminali adacquatori

Con le lance a braccio oscillante la

massima versatilità viene ottenuta

tramite la possibilità di sostituire i

boccagli, in modo da ottenere la

frantumazione più adatta della vena

liquida in relazione alle caratteristi-

che del terreno e della coltura in at-

to. Viceversa, le ali piovane e le bar-

re irrigatrici hanno il vantaggio di la-

vorare a bassa pressione, con un ri-

sparmio energetico fino al 50% ri-

spetto alle lance a lunga gittata. In-

fatti, le nuove ali piovane in acciaio

zincato o alluminio sono in grado di

offrire coperture fino a 50 m per

passata, assicurando tra l’altro una

nebulizzazione ottimale dell’acqua.

Servocomandi idraulici

L’applicazione generalizzata sul roto-

lone di servomeccanismi a movimen-

Watering terminals

Maximum versatility with a lance on an oscillating boom is

achieved by the option to replace the mouthpieces to obtain

the atomization most suitable for the water flow in relation

to the characteristics of the soil and growth stage of crops.

On the other hand, sprinkler booms and irrigation bars have

the advantage of operating a low pressure to save energy by

up to 50% compared to the long jet lance. In fact, new sprin-

kler booms in galvanized steel or aluminum are capable of

coverage at distances of up to 50 m with each pass while op-

timizing the atomization of the water.

Hydraulic servo control

The application of hydraulic movement servo mechanisms

on reels has make it possible for the operator to easily man-

age the machine, often by remote control via ratio. Examples

are opening the traveling cart gate and/or raising the irriga-

tion bar for changing location, rotating the swivel supporting

the hose, placing and anchoring equipment and placing the

suction pipe on models with a pump.

CPU management and control

A battery powered CPU sometimes integrated with a photo-

voltaic solar panel makes it possible to complete automation

of irrigation operations beginning with control of flow and the

speed of work on to programming the timing for beginning ir-

rigation and finishing for correct watering without moving the

components. Among the various solutions offered, Casella

markets the Hydro-Control 260 CPU, which can be equipped

with a GSM module. This means the computer can regulate

the starting watering time without rewind and opens and clos-

es the water flow to carry out watering in the correct way and

change the pre-programmed parameters during watering.

Moreover, the Hydro-Control provides a switchboard start key

for functions which include total monitoring of the parame-

ters and the performance of the pump. For fertigation, an-

other CPU is available for injecting liquid fertilizer on the pump

suction and allows splitting the doses to avoid losses.

Arrangements for road travel

Ensuring the required mobility of the equipment coupled to

57

n. 7-9/2016

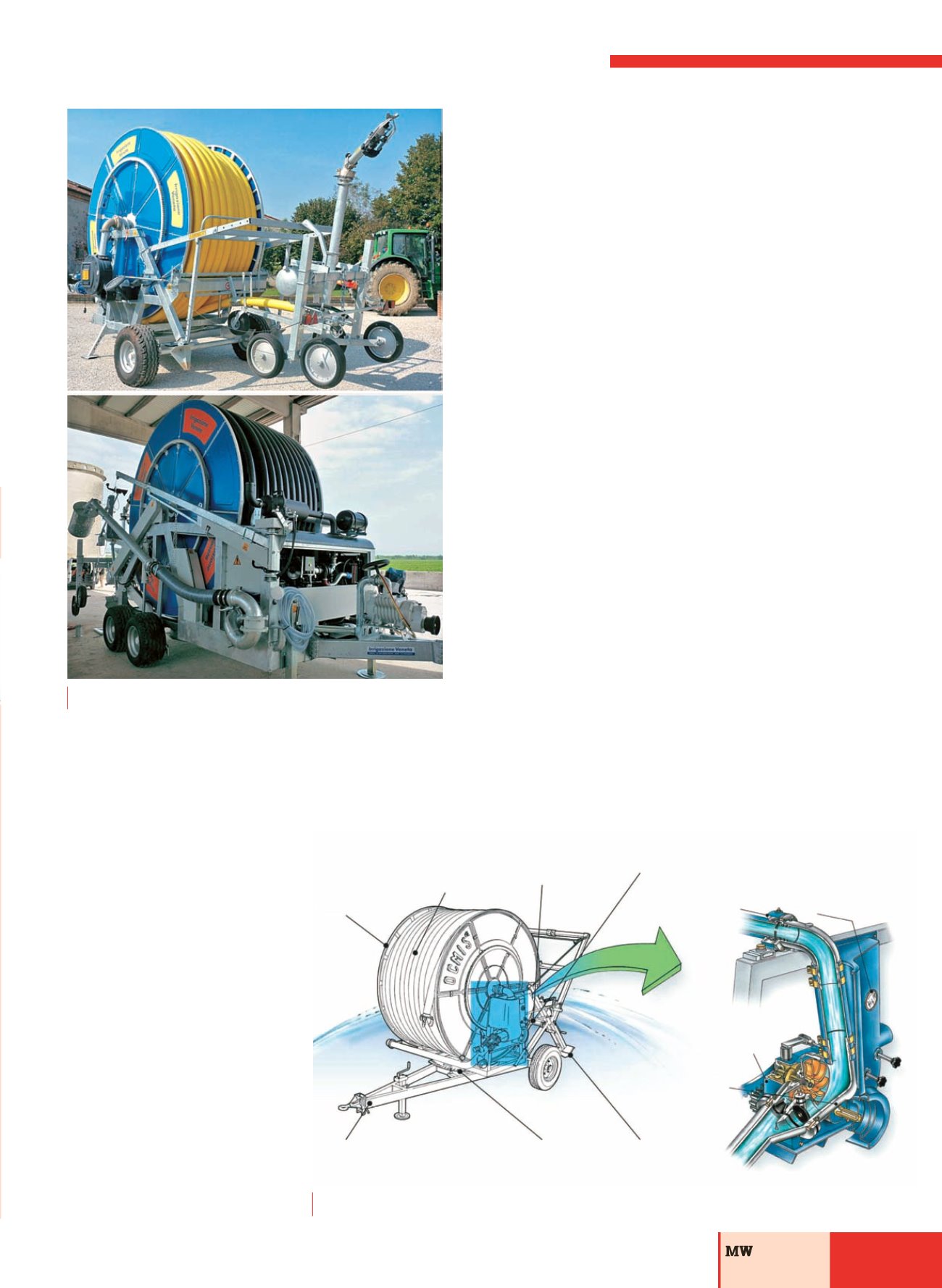

Due versioni di irrigatore a naspo, senza (sopra) e con motopompa (sotto)

Two versions of hose reel irrigator, with (above) and without pump (below)

Componenti base del meccanismo di svolgimento/riavvolgimento della tubazione di irrigazione (fonte: OCMIS)

Basic components of the lay out and re-coil of irrigation hose (source: OCMIS)

IRRIGAZIONE

|

IRRIGATION

Tamburo/

hose reel

tubo in PE

polyethylene hose

guida tubo a vite senza fine

hose guide with work gear

forcelle guidatubo

hose guide fork

cuscinetto di supporto tamburo

drum support bearing

contametri

water meeter

riduttore meccanico a più rapporti

mechanical reducer

with various speeds

turbina

turbine

piedini stabilizzatori

stabilizing feet

ralla girevole

pivot

timone con occhione

drawbar with eye hitch