tre 200 Cv sui modelli più performanti). La motopompa può

essere montata direttamente sul telaio dell’irrigatore a na-

spo, oppure essere autonoma, anch’essa installata su un

carrello per un agevole trasporto su strada. Quasi sempre

è presente una centralina per la gestione (anche in remo-

to) delle diverse funzioni. I modelli più performanti posso-

no essere equipaggiati con un verricello manuale o aziona-

to elettricamente per la gestione del tubo di aspirazione ed

essere incapsulati per l’insonorizzazione dell’intero gruppo.

Avvolgimento della tubazione

Il diametro della tubazione può variare da 30 a oltre 160

mm, così come in proporzione il suo spessore; il materiale

adottato modernamente (polietilene) assicura ottime ca-

ratteristiche di elasticità, resistenza alla trazione e all’usu-

almost always equipped with computer processing unit (CPU)

management control of the various functions, also by remote.

The most high performance models are equipped with a man-

ual or electric motor water abstraction system which is en-

closed to soundproof the entire group.

Retracting hose

Hose diameters range from 30 mm to 160 mm and, in rela-

tion to their thickness, the modern material used for them is

polyethylene which ensures the optimum characters of elas-

ticity and resistance to dragging and wear for excellent use

on rough and abrasive surfaces.

The mechanism for pulling them out and in is a key compo-

nent on the hose reel irrigator because the uniformity of wa-

ter distribution, reducing load loss, the accurate regulation of

55

n. 7-9/2016

A considerable investment is required for the purchase of a

hose reel irrigator, especially a high capacity model, so the in-

tention is to have a machine guaranteeing efficiency over time

and especially one which can be transferred on the road and

public highways. The mechanical, hydraulic and electronic com-

ponents of a hose reel irrigator are mounted on the frame which

must be treated to ensure long term resistance to corrosion, a

consideration to take note of because of the typical field of the

machine’s operations, dealing continuously with water and some-

times also slurry.

For this reason, painted surfaces are usually given treatments

which begin with pickling of the steel, followed by a double coat

electrostatic painting job, which provides excellent covering even

of the most hidden parts and involves a modern base treatment

and water based ecological finish. Each step is finished with

baking, normally at 60°C to guarantee great resistance to cor-

rosion and UV rays.

For travel on public highways a hose reel irrigator must have

type-approval, that is, be equipped with all the components nec-

essary named in the Highway Code of laws and European Union

Directives for trailed agricultural machinery.

Starting with what is needed for coupling the machine to the

tractor is a drawbar with an eye hitch which can be regulated

for height for correctly hitching it to the

tractor. The drawbar itself, mounted on

the main frame, is usually built with

welded tubular steel supported either

by a single axle or two close axles with

tires which may have wide treads to re-

ducing compaction during transit in the

field. For this purpose, RM Irrigation

Equipment in S. Quirico Trecasali, near

Parma, markets an asymmetric rocker

axle to reduce the force of towing on

difficult terrain and guarantee the best distribution of weight in

steering to facilitate maneuverability. Nitrogen suspension is

mounted on some models to absorb shocks on irregular terrain

and reduce roll of the machine in transit. Due to the consider-

able weight and open construction of these machines they are

often equipped with hydraulic or air brakes which provide greater

efficiency than mechanical brakes and, above all, can operate

automatically in synchrony with the tractor. Another item of

equipment often mounted is soundproofing of the pump, if there

is one, as a useful option for reducing noise levels if the irriga-

tor is operated for long periods in the vicinity of populated ar-

eas.

Accessories

There is an extremely range of accessories for hose reel irriga-

tion covering practically all the main components of the machine.

For starters there are various versions of the traveling cart car-

rying the lances or oscillating sprinkler booms to be adapted for

the best watering practice. For the Turbocar series manufactured

by Idrofoglia in Lunano, in the Pesara Urbino province, various

versions are offered with under-foliage and over-foliage irrigation

adapters, for offset axis movement or high pressure distribution,

a water ballast tank and wheels in cast iron.

Durability

and

mobility

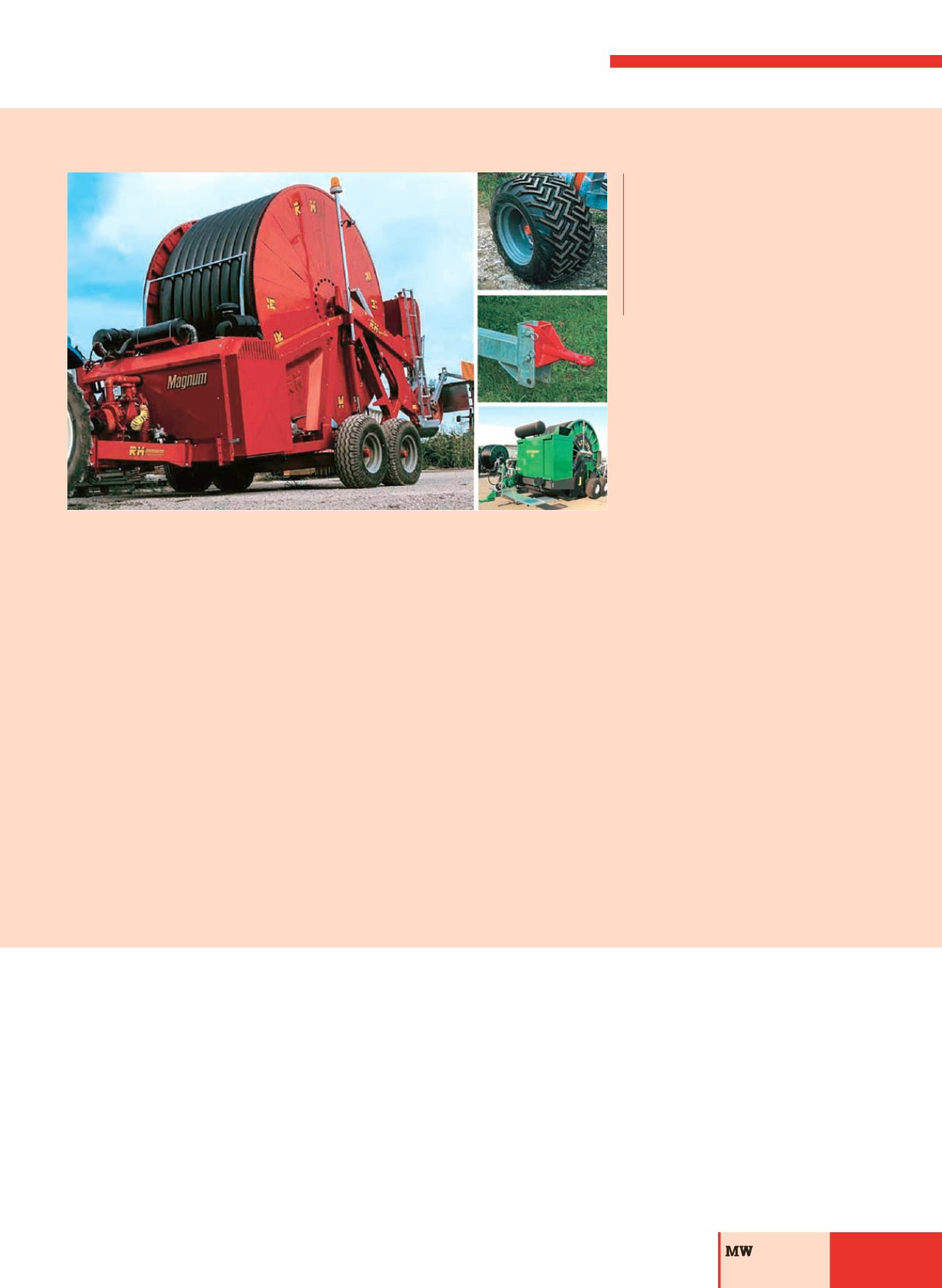

Alcune delle più moderne dotazioni degli

irrigatori a naspo: l’assale a bilanciere

asimmetrico (a sinistra), pneumatici a sezione

larga, occhione ad altezza regolabile e

motopompa insonorizzata (a destra, dall’alto in

basso)

Some of the modern components for equipping

hose reel irrigators are an asymmetric rocker

axle (left), wide tread tires, an eye hitch

regulated for height and pump soundproofing

(right from top down)

IRRIGAZIONE

|

IRRIGATION