Pruning – Easy and Safe

Vineyards, orchards and other trees need dry, winter pruning if they are to produce the desired yield. While maintaining the desired shape of the tree, pruning also decides how many buds should be left for the following year, a key factor in the quality and quantity of production

Winter pruning is a crucial part of training for agricultural workers employed in vineyards, orchards and other plantations since it is by pruning that the farmer decides how many and which buds mature the following year and, hence, how much and what quality of fruit the trees produce. The pruner must have a solid understanding of the physiology of the plant being pruned, and must be sufficiently knowledgeable to know which sprouts and branches should be removed and which left.

The basic equipment is fully manual: garden scissors, secateurs and the like. A cutting edge always kept fully sharpened slices through the pruned material using only the strength of the hands. Almost all available models have the same basic structure. The blades are attached to a handle made of a range of materials and are joined at a central joint by a bolt. There is a spring to push the blades apart again after each cut, so that the operator needs to do nothing to be ready for the next cut. A small catch holds the device safely closed when not in use. The biggest difference between models is the material used in manufacture for the blades and handles: steel, plastic or composites.

For more demanding cutting, scissor devices can be flanked by small saws and shears, the latter having one or more fulcrums to transmit the force applied and make it possible to cut branches of significant girth. The most common small saws fold back into the handle and can be easily and safety put away in a pocket when not in use.

Servo-assistance

The most widely used pruning tools are power-assisted, which reduces the physical effort required of the operator, who still has to decide what and where to prune. Hydraulic systems activated by compressed air or electricity are the only way to prune guyot trained vines or orchards.

Pneumatic secateurs are based on a small cylinder activated by compressed air and controlled by a trigger. The metal, or in cheaper models plastic body contains the piston, the blade and its fulcrum, and the trigger; the compressed air pipe is attached at the back. These are simple, strong and relatively cheap (a couple of hundred euros for the best models) pieces of equipment. But one thing to remember is that the cutting action is on-off; the blade runs its whole course once it has been activated, cutting anything in its path, including support wires or even a finger, if the user’s concentration wavers. The air pipe may also get mixed up in branches or undergrowth.

Box – Tractor-powered Air

Pneumatic pruners get their compressed air from a compressed mounted on a tractor’s three-point hitch and powered from the PTO. Independent compressors are another, but rarely used solution. The compressor, whether rotary, screw or piston powered fills a tank and guarantees high airflow at about 10-12 bar. Rubber piping whether simple or on an automatic reel can be used to link the machine to a number of pruners.

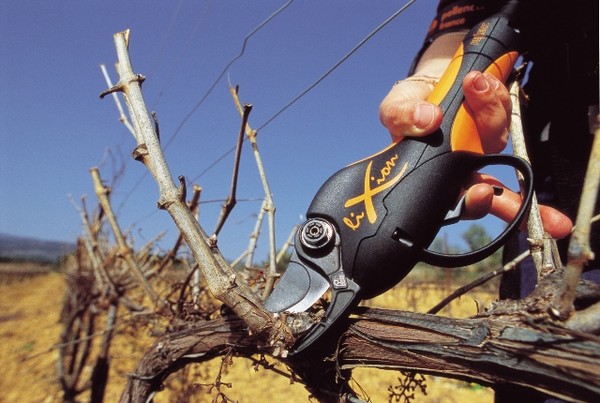

Electrical or electronic pruners are currently the most widely sold. Recent development has concentrated on improving the life of the lithium-ion batteries used to power them. High power loading has also made it possible to reduce their size and extend their life. With no direct connection to a power line, the risk of a lightning strike has also been eliminated.

The battery pack is now small enough to be worn by the operator on a special harness or waistcoat which leaves full freedom of movement. A robust, but flexible cable connects the batteries to the tool, usually made of high-resistance plastic, or in some cases aluminium. The control trigger does not control the blade directly, but through an electronic circuit, which can identify where it is. This can stop or start the blade, giving a big increase in safety.

The blade works off a small electric motor which can activate a pinion or a worm gear, the former acting directly on the blade, the latter moving a threaded shaft linked to the blade through a joint. The cutting part is relatively simple, but the electronic circuit is rather complex since it has to manage both the pruner and the battery, communicating with the user through displays. The most important information is the remaining battery power, but other information such as the length of the current session or the number of cuts made is also available.

Mechanised Pruning

Mechanised pruning has been developed only for vineyards and only in those vineyards with specific types of vine training such as GDC, spurred cordon etc. In these cases, mechanised pruning has been gaining ground because it permits significant cost reductions. Pruners, or pre-pruners if manual pruning will be needed to complete the job, are usually front-mounted on a tractor, even if there are also straddle-row models, also used for example on harvesters with interchangeable tool heads. Pre-pruning and manual completion can be used on Casarsa trained vines, but fully mechanised pruning is possible only on spur training. Even in this case, mechanical and manual pruning must be alternated to ensure that vines’ development is fully respected.

The machine’s cutting disks or flails are mounted on a basic structure whose height and distance from the vines are controlled hydraulically through cylinders linked to the tractor’s hydraulic circuit. Rotary pruners have a double column of horizontal toothed disks, which fit together working from both sides of the row. The number of disks decides the form and type of prune required. The disks channel the cut vegetation concentrically, crushing and cutting up the wood. Thanks to feelers, the columns open up automatically when they pass a post. Cutting flails are identical to normal bush toppers, but stronger because they have to cut dry wood. They can be used effectively only on Casarsa trained vines.